Bhal Nalkantha Khadi Gramodyog Mandal is a Khadi institution located in Ranpur, Botad District of Gujarat, India. This Institute's Vision is to provide employment to the local women by involving them into the work of spinning, handloom weaving, hand knitting, Dyeing and stitching of woolen khadi products.

Bhal Nalkantha Khadi Gramodyog Mandal was established by Ambubhai Shah, Harivallabh bhai Mehta, Dajibhai Dabhi, Chaturbhai Patel with the blessings of Jain Muni Shri Santbalji in 1958.

PALUBEN CHHAGANBHAI VAGH a knitter from this institution was awarded as "BEST MAHILA VIKAS" by the Chief Minister of Gujarat, Narendra Modi. On 31st March, 2012

Our Prime Minister has given the slogan that Vocal for Local and i That spirit is well maintained here. By the Government assistance, The work and sale of khadi is increasing through promotion and publicity, It is helping the villagers to become self-reliant. If every person in India buys at least one item of khadi So many people can stand on their own feet. For Gandhiji's Khadi Insistence is just as welcome today as it was in the past. Stimulation of Swadeshi will be the foundation of development of the same village. That is a matter of course.

Happy Clients

Product

Workers

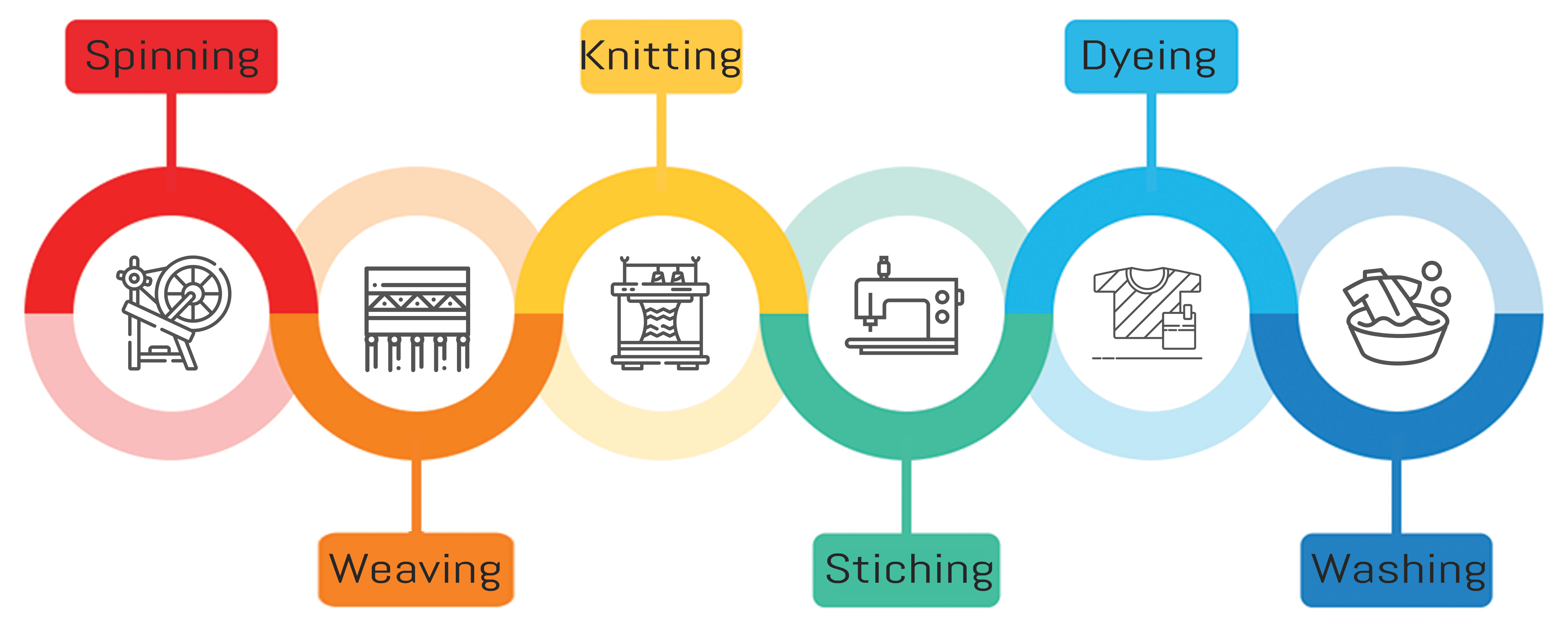

The Artisans of Khadi Gramodhyog Mandal are engaged in the following activities:

.png)

Raw wool is sent to the nearby villages where spinning is done by the local women. They came to the institution once a week to take raw material and submit

.png)

The conventional Charkha was. used when the organization started in 1961-62 but the introduction of Amber Charkhai resulted in upto four times production then the conventional Charkha. The fineness of yarns was achieved with the help of Amber Charkha thus improving the quality of the yarn as fine. as 20 to 25 yarn counts.

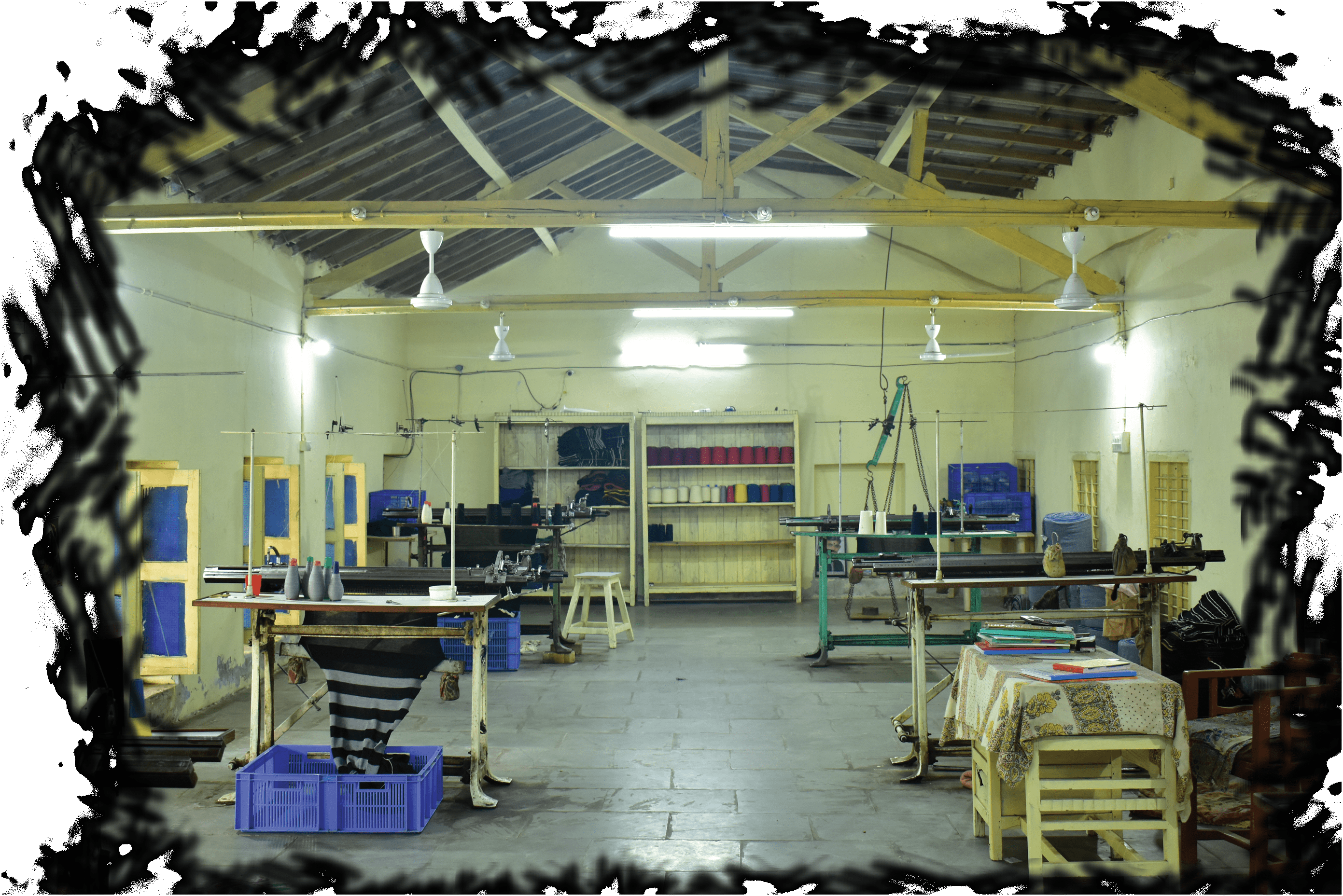

Weaving is done by weavers in the campus only. A pit and farme loom is used for weaving producing various

All the process from refilling of yarns in bobbins and reels to Weaving is done.

Charkha is used to refilling the yarns. The Beem(winder for wraping) is used for wraping in the

Initially Knitting was started by the Organization but later it was it was switched to Marino. Marino wool is out sourced as the supply could not meet the demand by the in-house production.

A Stiching department is setup for stiching, cutting and ironing. A cutting expert supervises the department to ensure best quality products.

Minimum required cutting is done by the cutting master and stiching is done for the Product development by the women artisans

The wool dyeing technique is mastered by the artisans employed with the i organization. Dyeing is mainly done for knitted and ready products.

The organization have in-house Winch & other Auxiliary machines. Apart from this a highly qualified dyeing master is also present to monitor the intricacies of dyeing.

Washing is also done to remove excess color and dirt and also to ensure the color quality before send is to selling outlet.